Foundary Tooling

Price 50000 INR/ Piece

Foundary Tooling Specification

- Working Process

- Die Casting

- Usage

- Industrial

- Size

- Different Sizes Available

- Mould Base

- Hardened Steel

- Tolerance

- 0.005 mm

- Life Span

- 50000 shots

- Core Material

- Aluminum

- Material

- Aluminum

- Shaping Mode

- Casting

- Punch Dies

- Steel

- Die Head

- Customizable

Foundary Tooling Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Foundary Tooling

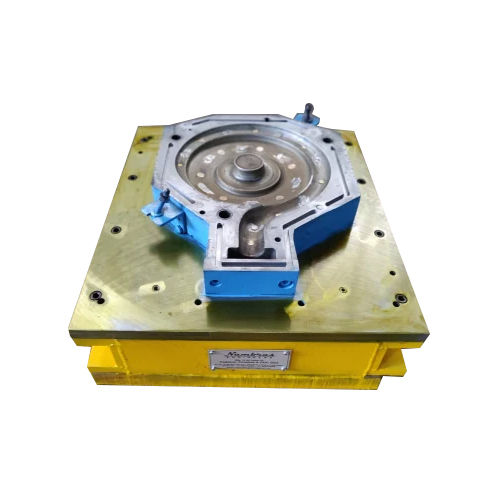

Sand Foundry Pattern is a process of sand casting that creates a pattern that is the replica of the original object to be cast. These patterns are used to make a negative cavity into which molten metal is poured during the casting process. It is typically used in sand casting that includes plastics, metal, wood and urethane. Sand Foundry Pattern is primarily used to clean, uniformly sized, high-quality silica that is bonded to form molds for ferrous and non-ferrous metal castings. These are offered at the markets best price which makes it the best choice.

WE ARE MANUFACTURERS OF PATTERN TOOLINGS FOR AUTOMOBILE, RAILWAYS & OTHER INDUSTRIES

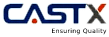

PATTERN MATERIAL AS REQUIRED TO CUSTOMERPrecision Split Pattern Tooling for Sand Casting

Each tooling set is engineered with split pattern designs, allowing for complex shapes and easy pattern removal during sand casting. Crafted from high-quality aluminum with a robust steel base, these tools ensure consistent results batch after batch, complemented by a polished finish for minimal friction and excellent surface quality.

Exceptional Durability & Temperature Resistance

Our tooling withstands temperatures up to 450C, making it suitable for demanding industrial casting operations. With a lifespan of 50,000 shots and a hardened steel mould base, it provides longevity and stability in high-use manufacturing processes. The water-cooling system ensures thermal stability, extending the life of the tools.

Custom Solutions Built to Your Specifications

Every order is tailored to client requirementsbe it size, die head, or punch dieswith designs made precisely as per provided drawings. Our tools meet strict ISO 9001 standards, guaranteeing reliability and uniformity across all produced components, perfect for a wide range of industrial applications.

FAQs of Foundary Tooling:

Q: How is the split pattern design beneficial in sand casting applications?

A: The split pattern design allows for easier removal of the pattern from the mould, especially when working with complex geometries, ensuring high dimensional accuracy in sand casting and reducing the likelihood of defects during production.Q: What cooling method is used for this foundry tooling, and why?

A: Water cooling is utilized to maintain optimal temperatures during operation, ensuring consistent performance, improved tool lifespan, and minimizing potential thermal deformation.Q: Where are these tools manufactured and supplied from?

A: All tooling is manufactured and supplied from our facilities in India, where we combine advanced production techniques and strict ISO 9001 quality controls for industrial customers globally.Q: What materials are used in the construction of this tooling?

A: The primary tooling components are made from premium aluminum for the core and body, while the mould base is fabricated from hardened steel, and steel punch dies are incorporated to ensure strength and extended operational life.Q: When should I consider replacing the tooling?

A: Tooling is designed with a lifespan of up to 50,000 shots. It is advisable to replace or refurbish the tools upon nearing this cycle count, or sooner if there are signs of wear, to maintain part quality and production efficiency.Q: What is the typical tolerance achieved with this tooling?

A: Our foundry tooling is engineered to achieve tight tolerances, with dimensional accuracy up to 0.005 mm, which is ideal for high-precision industrial casting requirements.Q: How do I benefit from using your foundry tooling in my manufacturing process?

A: By using our tooling, you benefit from reliable performance, extended tool life, precise casting with minimal defects, and flexibility to match your exact production needsall while adhering to strict international quality standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Foundry Pattern And Core Box Category

Railway Casting Pattern

Price 50000 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Steel

Usage : Industrial

Size : Different Sizes Available

Working Process : Other, Precision sand casting

Aluminium Foundry Casting Patterns

Price 30000 INR / Unit

Minimum Order Quantity : 10 Units

Material : Aluminum

Usage : Industrial

Size : Different Sizes Available

Working Process : Stamping

Aluminium Pumps Foundry Pattern

Price 50000 INR / Unit

Minimum Order Quantity : 10 Units

Material : Aluminum

Usage : Industrial

Size : Different Sizes Available

Working Process : Stamping

Industrial Foundry Pattern

Price 75000 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Aluminum

Usage : Industrial

Size : Different Sizes Available

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS